LAMBDA CuCrZr Combustion Chamber

Partner: 3T AM

Funding: UKSA Pathfinder Grant

Partner: 3T AM

Funding: UKSA Pathfinder Grant

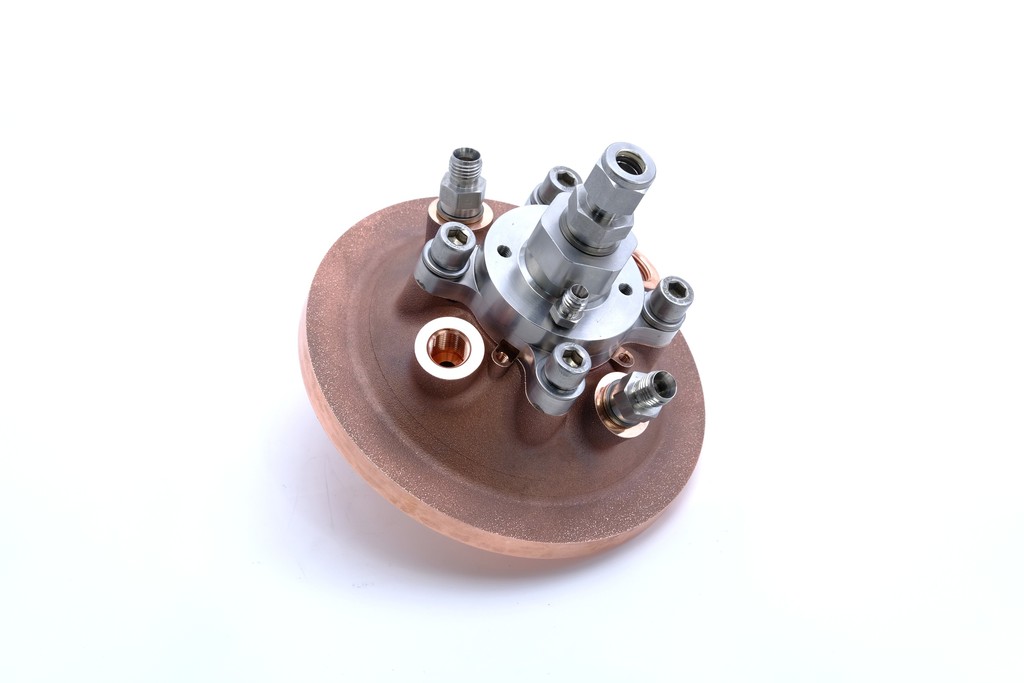

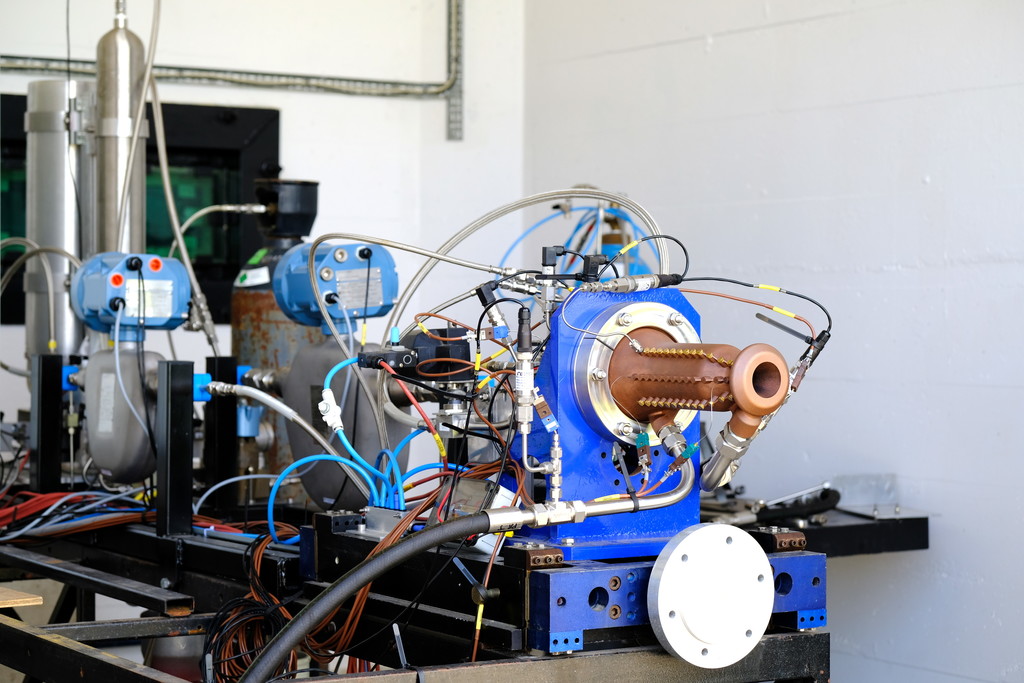

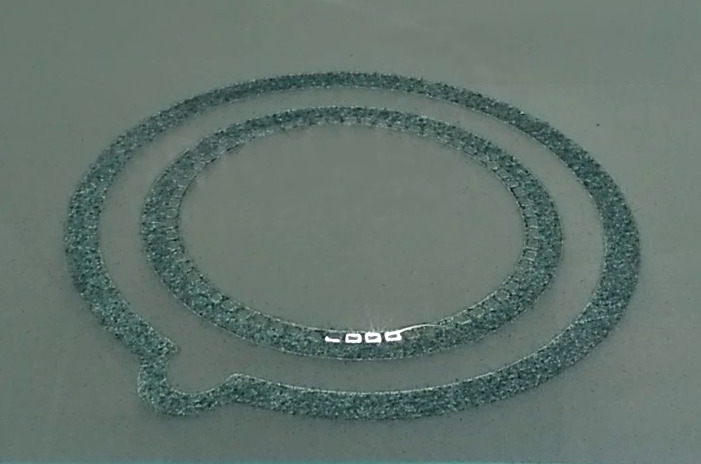

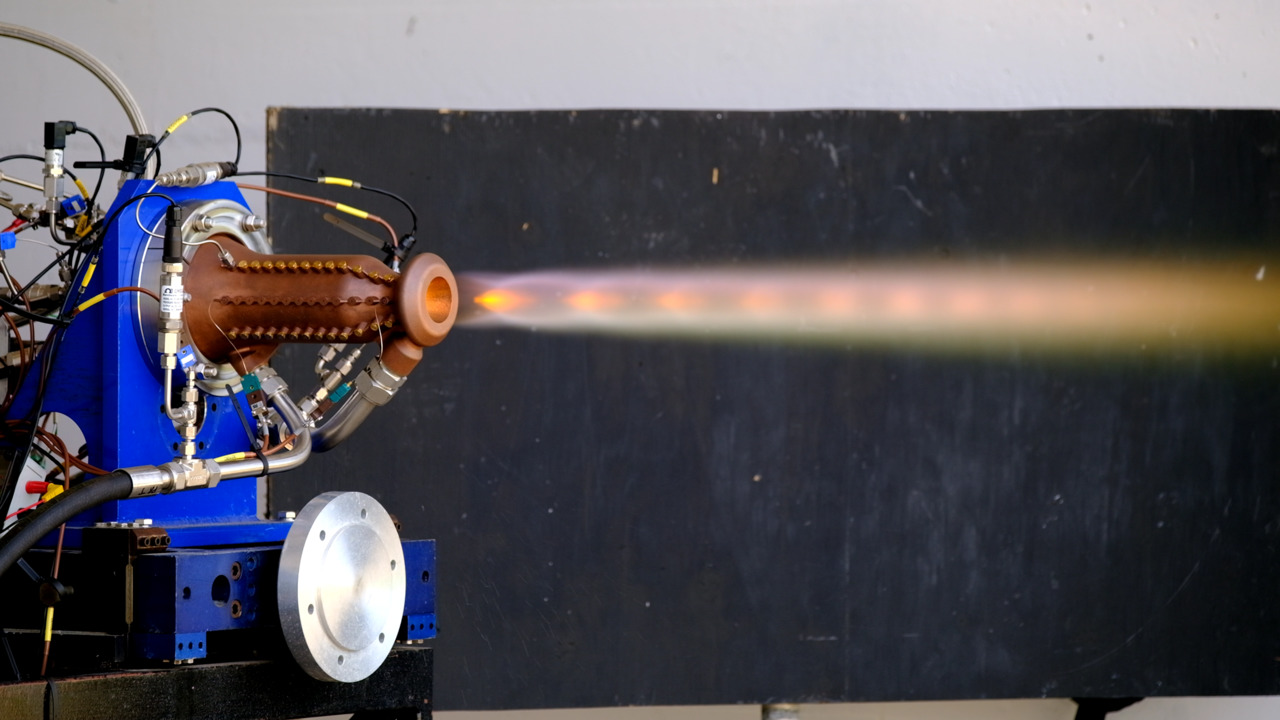

This programme evaluated the suitability of using CuCrZr for additively manufacturing rocket engine combustion chambers, under a UKSA Pathfinder grant with maunfacturing partner 3T AM. Small test pieces were printed in CuCrZr to analyse the flow properties of various printed geometries. These included a full combustion chamber and injector head printed in CuCrZr, with a conventionally machined throttleable pintle injector.

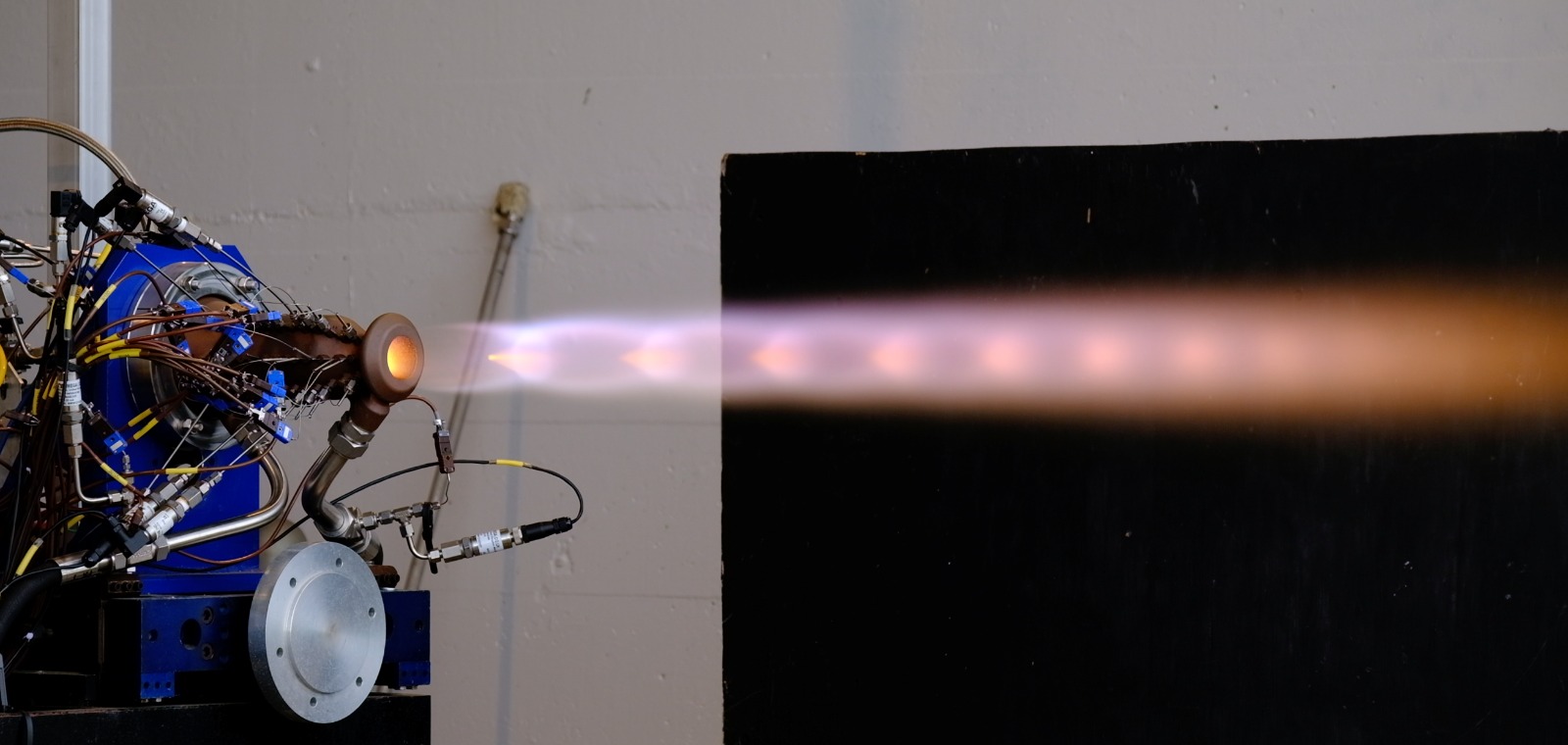

This combustion chamber was fired using a liquid bipropellant test rig built for the programme. To our knowledge, the hot-firing of the CuCrZr combustion chamber is the first firing of a liquid rocket engine combustion chamber in the UK built with additive manufacturing from metal alloys, and the first firing of an AM copper combustion chamber in Europe. The chamber has subsequently been used as a workhorse chamber for heat transfer and injector studies.