MCHX Heat Exchanger

Customer: Reaction Engines Ltd

Customer: Reaction Engines Ltd

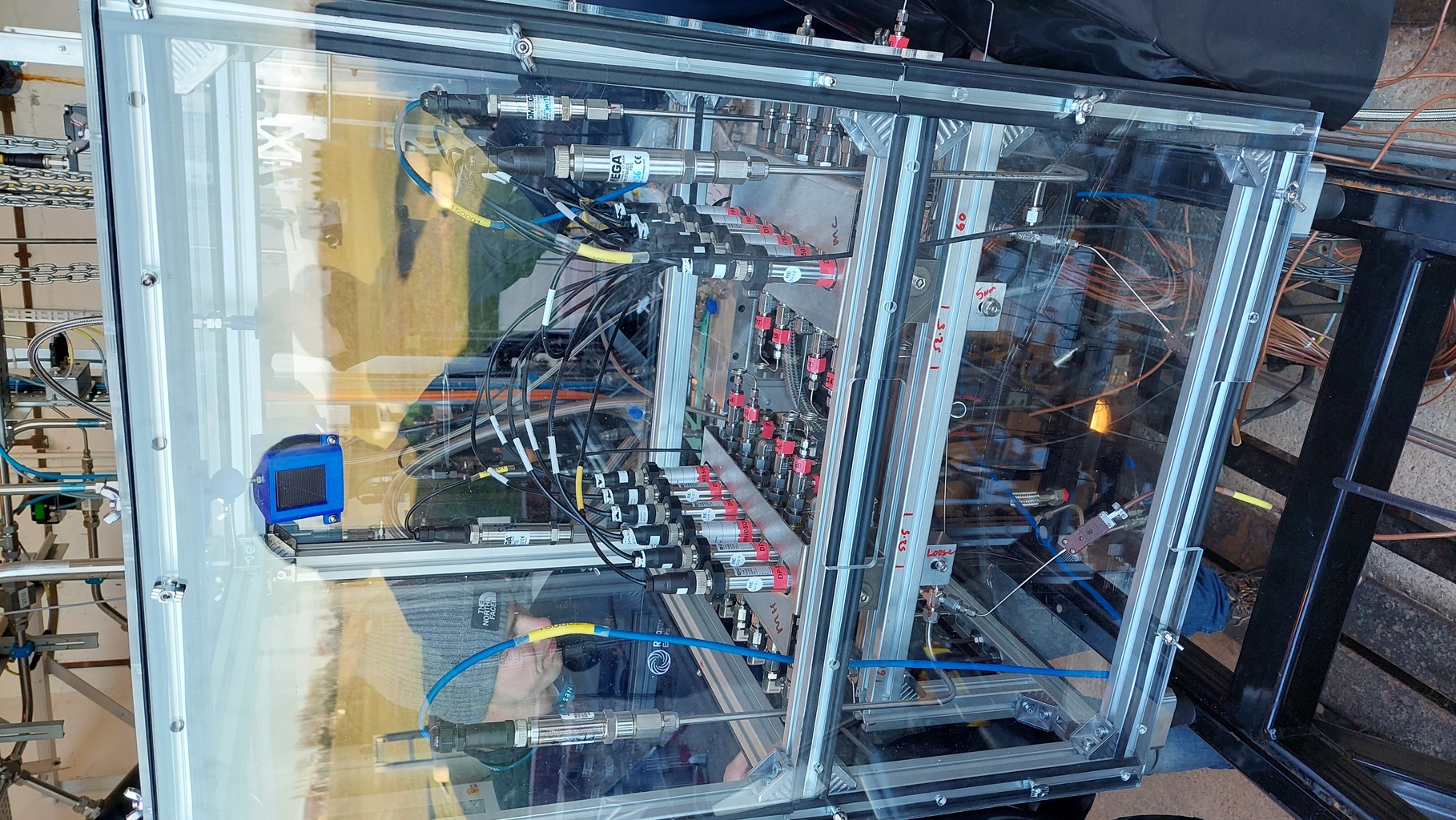

This test campaign studied the performance of a microchannel heat exchanger developed by Reaction Engines. The heat exchanger transferred heat from a flow of ambient temperature helium to a separate flow of helium at -180°C (90K). This required AEL to provide two high-pressure helium supply lines, each with massflow feedback-controlled to better than 0.5% accuracy, and adjustable outlet chokes to maintain backpressure of the helium on the outlet of the experiment. A custom liquid nitrogen boiler was manufactured by AEL to pre-chill the supply of helium coolant. This consisted of a tube coil inside a large drum filled with liquid nitrogen. Heat exchanger temperatures and pressures were measured, supported by thermal imaging of the experiment in a nitrogen-purged box to prevent icing.